Forest Master – Frequently Asked Questions

Explore a range of frequently asked questions regarding our equipment, as well as general log splitting, gardening and forestry-related questions. Is your question not here? Submit a question by emailing us at info@forest-master.com.

FM4DDE 4HP Electric Chipper

Last Updated on October 8, 2020 by Forest Master

First, you will need to check the main supply voltage.

The extension cable you use will also have to be 2.5 cable and be used full unwound.

On average, we lose 1 volt of power for every meter of cable. So if you were to extend over 30 meters then you’re losing 30 volts of power. When a motor is designed for 230/240 volts you are overloading the motor by running it with less than 220 volts.

In the past, customers have been known to run at 200 volts with no issues but over time this can cause issues with the motor causing them to fail.

Standard household mains will typically run at around 230v/240v but it’s recommended that you check this as it’s quite possible that you’re running at a lower level.

General Product Queries

Last Updated on October 8, 2020 by Forest Master

First, you will need to check the main supply voltage.

The extension cable you use will also have to be 2.5 cable and be used full unwound.

On average, we lose 1 volt of power for every meter of cable. So if you were to extend over 30 meters then you’re losing 30 volts of power. When a motor is designed for 230/240 volts you are overloading the motor by running it with less than 220 volts.

In the past, customers have been known to run at 200 volts with no issues but over time this can cause issues with the motor causing them to fail.

Standard household mains will typically run at around 230v/240v but it’s recommended that you check this as it’s quite possible that you’re running at a lower level.

Log Splitter - Small Dysfunctional Parts

Last Updated on August 27, 2020 by Forest Master

Check that the plastic knob of the lever is screwed on fully. If this becomes unscrewed it prevents the lever from being pushed right down, stopping the log splitter from operating. View the video below for a demonstration:

Petrol & Electric Log Splitters

Last Updated on August 27, 2020 by Forest Master

Check that the plastic knob of the lever is screwed on fully. If this becomes unscrewed it prevents the lever from being pushed right down, stopping the log splitter from operating. View the video below for a demonstration:

Log Splitter - Operation

Last Updated on August 27, 2020 by Forest Master

Check that the plastic knob of the lever is screwed on fully. If this becomes unscrewed it prevents the lever from being pushed right down, stopping the log splitter from operating. View the video below for a demonstration:

Log Splitter - Power Issues

Last Updated on August 27, 2020 by Forest Master

Check that the plastic knob of the lever is screwed on fully. If this becomes unscrewed it prevents the lever from being pushed right down, stopping the log splitter from operating. View the video below for a demonstration:

Last Updated on July 21, 2020 by Forest Master

First, close the bleed screw and turn the machine upside down.

You will then see 3 vertical bolts at the rear which fasted the pump bracket to the underside of the end cover, and a horizontal bolt at the top of the motor end cover.

Remove these 4 bolts and the complete assembly lifts clear.

There are two O-Rings in the top of the pump bracket, these can be reused.

You can purchase a new motor and pump assembly using this link : https://forest-master.com/product/2200w-motor-and-pump-assembly/

Last Updated on April 20, 2020 by Forest Master

Check fuse in plug. If blown replace with a working 13 amp fuse. Check RCD for the ring main has not tripped.

If the RCD has tripped, try the machine on a separate ring main. If it repeatedly trips, unplug all other equipment from sockets on the ring main and switch these sockets off. Try to start the motor.

Last Updated on April 20, 2020 by Forest Master

Check motor turns freely, remove the black fan cover. It should be possible to turn the fan with slight pressure from one finger. If not check for obstructions of the fan.

Last Updated on April 20, 2020 by Forest Master

Check that the nut securing the lever is fully tightened.

Check that the face of the lever that operates the valve is bent through a full 90 degrees in relation to the mounting face. If not, remove the lever and correct the bend in a vice.

Last Updated on April 20, 2020 by Forest Master

Loosen each of the 6 bolts on the back of the pump by ¼ of a turn and check if the motor turns freely.

Last Updated on April 20, 2020 by Forest Master

Remove the 6 bolts from the pump and separate the motor and pump. Check the gears for any silicone sealant or other material. When reasembling, the torque for the bolts is 12 ft lb, 16 N m.

Last Updated on April 14, 2020 by Forest Master

A humming noise will result in the log splitter blowing a fuse and typically means that the motor is tight.

First, turn the log splitter over and close off the air vent, remove the motor and pump 3 x 13mm headed bolts and 1 x support bolt.

Place the log splitter back upright and try the splitter again, if it produces the same noise then loosen the bolts a little from the end of the pump (13mm) and try again.

If this process does not work, then contact us on our technical line on +44 0191 276 6553.

Last Updated on August 3, 2020 by Forest Master

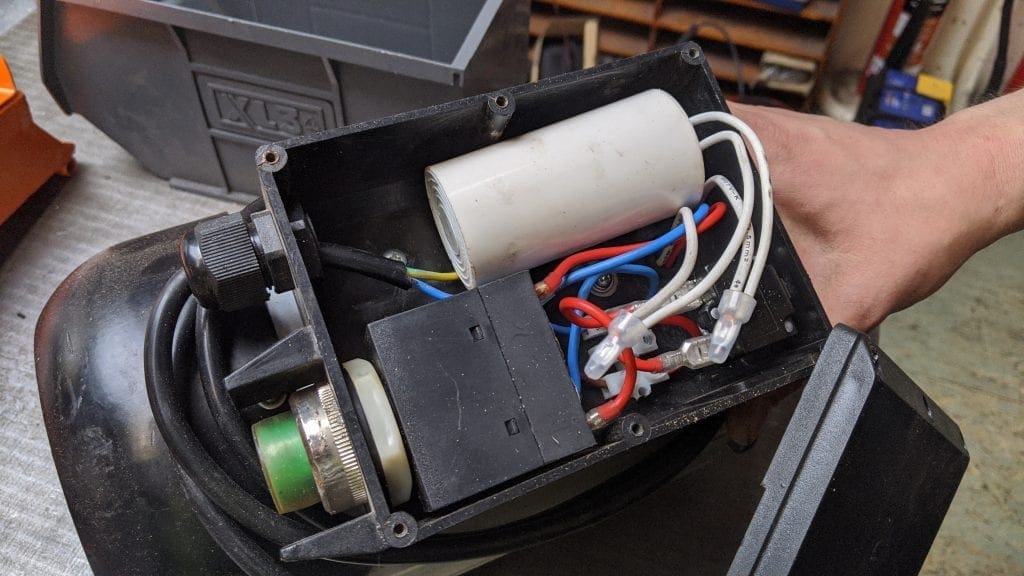

The capacitor in the electric motor can fail from misuse over time. When operating the log splitter, we strongly advise that you press the power button before operating the lever, this allows time for the motor to gather speed before attempting to split logs.

Pressing the lever before the button can also often result in blown fuses.

There are many different reasons why there may not be any power to your log splitter:

If you’re using an extension lead, ensure that the extension cable itself is a wider diameter than the power lead of the electric log splitter.

It’s also possible that the fuse has blown, these are easy and cheap to replace, we offer spares on our website. We also recommend testing the plug socket itself by testing another machine on the same socket.

As stated in the title, the capacitor failing will also stop the motor from starting up. After you have checked the previous solutions, unplug the log splitter from the mains. Then remove the six screws on the outside of the switch cover, take the switch cover off and you will then see the capacitor.

If the capacitor has failed, you will sometimes see burn marks on the capacitor itself.

Replacement capacitors are available on our website – Click here to purchase.

Last Updated on October 8, 2020 by Forest Master

First, you will need to check the main supply voltage.

The extension cable you use will also have to be 2.5 cable and be used full unwound.

On average, we lose 1 volt of power for every meter of cable. So if you were to extend over 30 meters then you’re losing 30 volts of power. When a motor is designed for 230/240 volts you are overloading the motor by running it with less than 220 volts.

In the past, customers have been known to run at 200 volts with no issues but over time this can cause issues with the motor causing them to fail.

Standard household mains will typically run at around 230v/240v but it’s recommended that you check this as it’s quite possible that you’re running at a lower level.

Last Updated on November 3, 2020 by Forest Master

In order to check if the electric motor is suffering from water damage, you need to first remove the motor and pump assembly.

Close the bleed valve of the log splitter and turn the machine upside down. There are three vertical bolts that hold the pump bracket to the underside of the end plate and a fourth horizontal bolt at the top of the rear motor cover. Remove these bolts and lift the assembly clear. There are 2 small O’Rings between the pump bracket and the end plate, make certain you do not lose these.

Next, remove the 6 bolts holding the pump bracket to the pump plate and remove the pump bracket. Check that there is no silicone sealant trapped in the pump gears. Try turning the fan again to check if the gears are turning okay.

If the gears are fine, then it’s likely the motor has suffered water damage. Withdraw the shaft locating the upper gear and the lower gear. There is a small ball bearing located on the gear of the shaft, do not lose this.

Next remove the gear from the motor shaft. There is a cylindrical key in a solot in the shaft, remove this key. You can then remove the 3 long bolts that run from end to end of the motor and remove the motor end cover.

If there is water damage, you will see white deposits inside the aluminium casing and more than likely notice a strong pungent smell. If this is the case, the motor will need to be replaced.

Log Splitter - Ram

Last Updated on August 27, 2020 by Forest Master

Check that the plastic knob of the lever is screwed on fully. If this becomes unscrewed it prevents the lever from being pushed right down, stopping the log splitter from operating. View the video below for a demonstration:

Log Splitter - Fails to Split Logs

Last Updated on August 27, 2020 by Forest Master

Check that the plastic knob of the lever is screwed on fully. If this becomes unscrewed it prevents the lever from being pushed right down, stopping the log splitter from operating. View the video below for a demonstration:

Log Splitter - Carriage

Last Updated on August 27, 2020 by Forest Master

Check that the plastic knob of the lever is screwed on fully. If this becomes unscrewed it prevents the lever from being pushed right down, stopping the log splitter from operating. View the video below for a demonstration:

Can’t find your question? Submit it below.