Forest Master – Frequently Asked Questions

Explore a range of frequently asked questions regarding our equipment, as well as general log splitting, gardening and forestry-related questions. Is your question not here? Submit a question by emailing us at info@forest-master.com.

6HP Petrol Mulcher (FM6DD-MUL)

Last Updated on July 30, 2021 by Forest Master

Wood is too dried out

The compact chipper series is designed primarily for chipping freshly cut wood. The FM6DD has been tested thoroughly chipping freshly cut hawthorn wood (slow-grown hardwood).

We recommend that the wood is chipped no longer than three days after cutting. After this date, the wood will begin to dry out, meaning the chipper blades then struggle to dig into the wood. This produces a sawdust-like waste from the exit chute, and the chipper will struggle to self-feed.

If the chipper is producing sawdust – this is a clear sign that the wood is dry. When chipping slow-grown hardwood like fruit trees (such as cherry or apple trees) you must ensure that you chip the material the same day that it is cut to ensure the machine operates at full effectiveness.

Last Updated on August 10, 2021 by Forest Master

This largely depends on the hardness of the wood you’re chipping. The harder the wood, the quicker the blades will need to be replaced.

However, the chipper is equipped with twin reversible blades. The reversible blades mean that you can simply switch the blades around when the first set start to dull, so you get a much longer life span on the blades.

We also stock spare blades on our website, should you need to have them replaced.

You can also sharpen your blades using an oil stone. Simply sharpen the edges of the blade, do not worry about taking out any dents or marks.

Last Updated on March 8, 2021 by Forest Master

The following is an addendum to the manual provided with the garden mulcher (8th March 2021)

Complete steps 1-4 of the FM6DD-MUL assembly instruction manual as usual. Before completing step 5 of the manual, perform the following instructions written below.

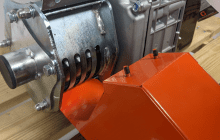

(1) First, place the engine/motor unit on its side as demonstrated in the image displayed below. Please ensure that the engine has not been filled with oil or petrol at this time.

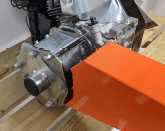

(2) You can now slide the discharge chute into the mulcher drum. The upper flange of the discharge chute should slide in above the bolt as displayed in the image to the left.

(3) After sliding the discharge chute into place, you can then secure and fasten the chute using the necessary M6 bolts (50), M6 spring washers (59) and M6 washers (41).

(4) After completing the aforementioned steps, you can then lift the engine/motor unit with the attached discharge chute on to the base of the mulcher and continue with the manual as standard.

Last Updated on March 16, 2021 by Forest Master

The mulcher is perfectly capable of receiving and processing wood branches, sticks etc. The material produced by the machine however will be 10mm down – you will not receive large wood chips from the wood placed into the machine. If you wish to process wood into wood chips, then you will require our wood chipping accessory kit for the mulcher.

Last Updated on May 4, 2021 by Forest Master

If you have been working with wet material – you may wish to wash down the machine using a hosepipe. To perform this simply spray water down into the mulcher hopper feed while the engine is running. After you have finished hosing the mulcher down – leave the engine running for a few minutes to allow the machine to dry itself off.

Last Updated on May 4, 2021 by Forest Master

The FM6DD-MUL is perfectly capable of processing both paper and cardboard. However, cardboard can take the edge off the blades quicker than when using the mulcher to process standard green waste. If you see a drop in performance in the machine after processing cardboard, it’s likely because the sharp edge has been removed from the blades.

These blades can be sharpened using an angle grinder or you can purchase spare replacement blades directly from ourselves. Remember that the blades are also reversible so once one side dulls, you can simply reverse the blades over and use a fresh set.

Last Updated on August 9, 2021 by Forest Master

We have been made aware of an issue concerning the rotation of the mulcher drum. This issue is caused by the washer under the head of the bolts not being correctly flattened. Once these have been correctly flatted it leaves a gap that allows you to rotate the drum housing.

In order to solve this, tighten the three adjusting bolts on the drum and then loosen the three nuts until they are very loose. This should allow you to then adjust the angles and retighten at the angle you require.

Last Updated on November 6, 2024 by Forest Master

All LCT petrol engines used on Forest Master products are compatible with E10 fuel. However as chippers and mulchers tend to be used infrequently, we strongly recommend that you add a fuel stabiliser to E10 or use a fuel that has been blended for use in garden equipment.

If unstabilised E10 fuel is left in the engine for a period without the engine being used then it evaporates and leaves a powdery residue in the fuel lines and carburettor. When you next use the engine, the powdery residue can get into the carburettor jet causing fuel starvation problems and requiring the carburettor to be fully cleaned.

If you do not use a fuel stabiliser or a specially blended fuel then before storing the machine for more than a few weeks, you need to drain it of all fuel and clean and dry the float bowl so there is no fuel left in it.

FM4DDE 4HP Electric Chipper

Last Updated on July 30, 2021 by Forest Master

Wood is too dried out

The compact chipper series is designed primarily for chipping freshly cut wood. The FM6DD has been tested thoroughly chipping freshly cut hawthorn wood (slow-grown hardwood).

We recommend that the wood is chipped no longer than three days after cutting. After this date, the wood will begin to dry out, meaning the chipper blades then struggle to dig into the wood. This produces a sawdust-like waste from the exit chute, and the chipper will struggle to self-feed.

If the chipper is producing sawdust – this is a clear sign that the wood is dry. When chipping slow-grown hardwood like fruit trees (such as cherry or apple trees) you must ensure that you chip the material the same day that it is cut to ensure the machine operates at full effectiveness.

Last Updated on August 10, 2021 by Forest Master

This largely depends on the hardness of the wood you’re chipping. The harder the wood, the quicker the blades will need to be replaced.

However, the chipper is equipped with twin reversible blades. The reversible blades mean that you can simply switch the blades around when the first set start to dull, so you get a much longer life span on the blades.

We also stock spare blades on our website, should you need to have them replaced.

You can also sharpen your blades using an oil stone. Simply sharpen the edges of the blade, do not worry about taking out any dents or marks.

FM6DD 6HP Petrol Wood Chipper

Last Updated on July 30, 2021 by Forest Master

Wood is too dried out

The compact chipper series is designed primarily for chipping freshly cut wood. The FM6DD has been tested thoroughly chipping freshly cut hawthorn wood (slow-grown hardwood).

We recommend that the wood is chipped no longer than three days after cutting. After this date, the wood will begin to dry out, meaning the chipper blades then struggle to dig into the wood. This produces a sawdust-like waste from the exit chute, and the chipper will struggle to self-feed.

If the chipper is producing sawdust – this is a clear sign that the wood is dry. When chipping slow-grown hardwood like fruit trees (such as cherry or apple trees) you must ensure that you chip the material the same day that it is cut to ensure the machine operates at full effectiveness.

Last Updated on August 10, 2021 by Forest Master

This largely depends on the hardness of the wood you’re chipping. The harder the wood, the quicker the blades will need to be replaced.

However, the chipper is equipped with twin reversible blades. The reversible blades mean that you can simply switch the blades around when the first set start to dull, so you get a much longer life span on the blades.

We also stock spare blades on our website, should you need to have them replaced.

You can also sharpen your blades using an oil stone. Simply sharpen the edges of the blade, do not worry about taking out any dents or marks.

Last Updated on November 6, 2024 by Forest Master

All LCT petrol engines used on Forest Master products are compatible with E10 fuel. However as chippers and mulchers tend to be used infrequently, we strongly recommend that you add a fuel stabiliser to E10 or use a fuel that has been blended for use in garden equipment.

If unstabilised E10 fuel is left in the engine for a period without the engine being used then it evaporates and leaves a powdery residue in the fuel lines and carburettor. When you next use the engine, the powdery residue can get into the carburettor jet causing fuel starvation problems and requiring the carburettor to be fully cleaned.

If you do not use a fuel stabiliser or a specially blended fuel then before storing the machine for more than a few weeks, you need to drain it of all fuel and clean and dry the float bowl so there is no fuel left in it.

Can’t find your question? Submit it below.