Last Updated on August 9, 2022 by Forest Master

What is hydraulics?

Hydraulics is the term used to describe a mechanical function that operates through the force of liquid pressure, or a liquid moving in a confined space under pressure.

The most common applications of hydraulics can be seen in car brakes, mechanical arms on heavy construction vehicles, cranes and of course log splitters such as the FM10D-7-TC.

Why we use it

The reason hydraulics are so widely used today is due to how efficient the systems are and how much pressure can be generated using them. Hydraulic systems can apply far more pressure than pneumatic systems due to hydraulics using incompressible liquids rather than gasses. This means hydraulics can easily produce up to 10,000 pounds per square inch (psi) compared to 100 psi in pneumatics (25.5 ton and 0.05 ton respectively).

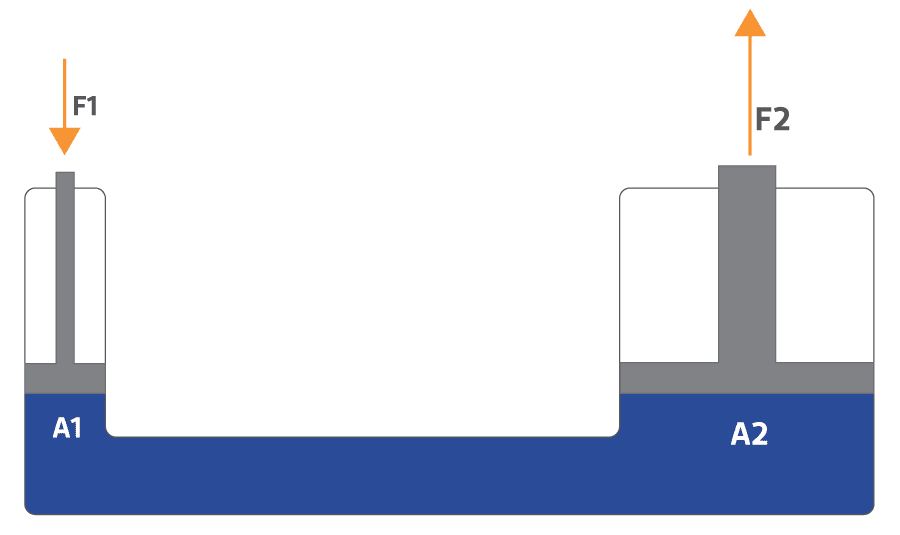

Force multiplication can be achieved by using a cylinder with a small diameter to push a larger piston in a larger cylinder. The larger cylinder will have a greater force output due to the larger surface area.

How it works

Pascal’s law (P=F/A) states that the pressure exerted upon an enclosed liquid is transmitted without loss, in all directions, to the interior of the container. This principle allows large forces to be generated with relatively little effort. As the liquid used in hydraulic systems is incompressible very little to no energy is wasted when transferring force through to the piston.

Incompressible liquids ensure the pressure applied from one end (F1) is transferred and equal to the pressure at the other end (F2) however, this means that to move a piston with a larger area (F2) the smaller piston will have to move further (F1).

Pascal’s Law Equations

Pressure = Force / Area

F1/A1=F2/A2

F2=(F1*A2)/A1

Real-world example, FM10D-7-TC 7-Ton Log Splitter.

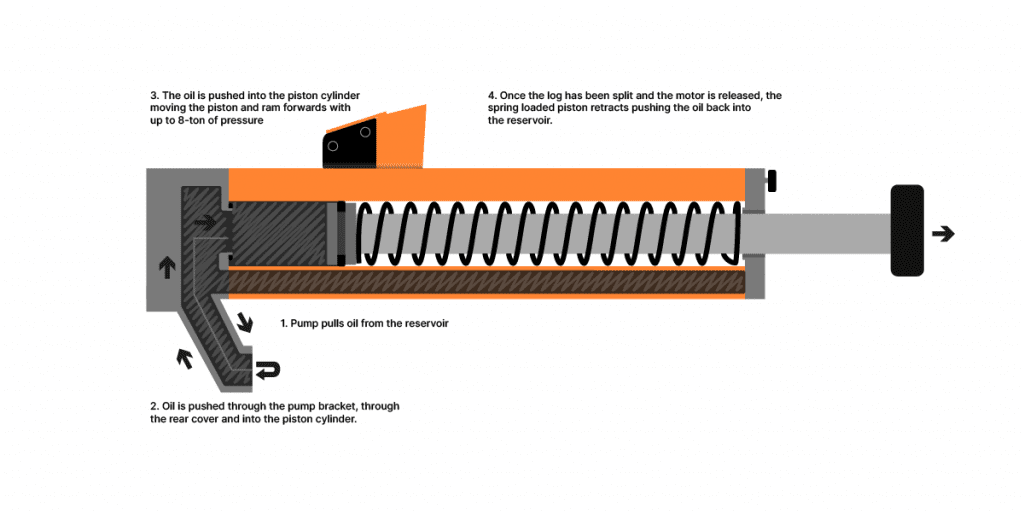

- 2200 W Electric motor powers the pump to pull oil from the reservoir.

- Oil is pushed through the pump bracket into the piston cylinder.

- Oil is pushed into the piston-cylinder moving the piston and ram forwards.

- Once the log has been split and the hand lever is no longer engaged, the spring-loaded piston will retract returning the ram and oil to their original positions.

Advantages

- Very efficient transfer of energy

- Can be either manual or powered systems

- Able to multiply input forces

- Self-lubricating

Disadvantages

- Sensitive to the environment (temperature)

- Not as effective over long distances

- Small leaks can cause significant issues with the operational efficiency of the system

- If the pressure is too high for the machine/system this can cause accidents or the machine to fail.

Conclusion

Hydraulics is a very useful and powerful technology that is almost unrivalled in pressure generation to size and efficiency, making it ideal for the application of heavy-duty machinery such as log splitters. They are not perfect systems however as if not cared for properly these systems can form a small fault that can be fatal to its operation.