Last Updated on March 15, 2022 by Forest Master

If you own a log splitter, you’re probably already conscious of hydraulic oil (unless you own a kinetic log splitter). Understandably, it’s a new area to many people and poses a lot of questions about how to correctly monitor the fluid levels to keep your log splitter running in tip-top shape. Not to worry, we’re going to go through everything you need to know without overwhelming you with technical information. Let’s get started!

This article covers:

- What is hydraulic oil?

- What kind of hydraulic oil is required for a log splitter?

- What is the best hydraulic oil for a log splitter?

- How often should hydraulic oil be replaced?

- How do I change/replace hydraulic oil in my log splitter?

- How do you know when a log splitter is low on fluid?

- How much hydraulic oil do I require for my log splitter?

What is hydraulic oil?

Hydraulic oil is the channel for transferring power within hydraulic machinery. The ram mechanism on a log splitter requires hydraulic fluid inside to provide the required power to split logs with ease. The fluid is also required for forklifts, aircraft, tractors, cruise ships and just about every other industry.

It’s important that the hydraulic fluid carries the correct properties for the operating conditions. It must be thermally stable, fire-resistant, non-corrosive and carry a constant viscosity as well as being long life.

What kind of hydraulic oil do you use in a log splitter?

Typically, the manufacturer of the log splitter will have a recommended oil available within the user manual. However, you should have an understanding of what you are looking at when buying. Viscosity is an important term to be aware of as it’s used to describe the fluid’s resistance to flow. Higher viscosity means a longer time frame to pass through an orifice. This means it’s thicker and harder to compress whereas a low viscosity indicates a thinner, more fluid oil.

The weather can also play an effect on oil viscosity and makes a low index viscosity thicker until it warms up. The ISO number displayed on hydraulic oil is the viscosity grade. You should choose a thinner option for cold weather and a midrange option for high heat.

What is the best oil for a hydraulic log splitter?

Forest Master Hydraulic Fluid is specially formulated to improve the performance of electric log splitters. Only virgin oils are used in the blending of HYD46+ fluid, this means that it lasts much longer without degrading compared to cheaper oils which are typically blended from recycled oil. The oil is designed to meet the requirements of today’s electric log splitters.

When replacing old fluid with our HYD46+, the log splitter will see a performance increase of up to 30%. It meets the essential properties required by electric log splitters.

Specification: Oxidation stability, corrosion protection, thermal stability, demulsification performance, air release performance, low foaming, filterability performance and seal compatibility.

How often should you change hydraulic fluid in a log splitter?

A lot of manufacturers will advise that you should change your fluid after every 50 hours. However, if the fluid used is of high quality this will usually give you around 150 hours of log splitting operation. This largely depends on the type of log and how hard it is to split, but 150 hours is the average benchmark.

If the system is kept clean and the hydraulic oil is clear, then generally the oil is fine to continue using until low.

How to change the hydraulic fluid in your log splitter

As instructed in our manuals; you should replace the hydraulic oil in your log splitter after every 150 hours of use.

First, ensure that all moving parts are entirely stopped and the log splitter is unplugged. You then unscrew the oil drain bolt with the dipstick to remove it.

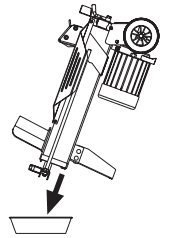

Make sure you have a 4 litres capacity container handy and then tip the log splitter onto the support leg (opposite end of the motor) to drain the hydraulic oil off.

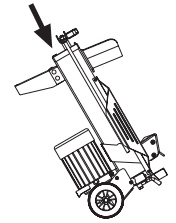

You can then tip the log splitter onto the motor end and refill with fresh hydraulic oil to the volume given for your model of log splitter.

Clean the surface of the dipstick attached to the oil drain bolt and screw it back into the oil tank while keeping the log splitter vertical.

Ensure that the level of the refilled oil is no more than 10mm above the first groove on the dipstick.

To finish; clean the oil drain bolt threads before re-inserting, making sure it is correctly tightened to avoid leakage before placing the log splitter horizontal.

How do you know when you need to top up the hydraulic fluid?

As you may have already discovered, it can be incredibly difficult to read a log splitter dipstick due to how clear the hydraulic fluid is. However, there are a few tricks to learn when you should think about topping up your fluid without even having to open the machine up.

If the fluid level is low, then you’ve probably already experienced a drop in performance. Logs your wood splitter once breezed through like butter to a knife is now whirring and being pushed to its limits. Raise the front of the log splitter (opposite end to the motor) on a block of wood or something similar. This pushed the fluid to the back of the log splitter and you’ll see an immediate boost in performance. This also tells us that the fluid levels are low.

How much hydraulic oil do I need for my log splitter?

The majority of log splitter hydraulic fluid reservoirs will allow between 3.5 to 7 litres, largely depending on the size and power of the log splitter. It’s best to be certain about this and check with the product manufacturer before committing to a purchase.

A full reservoir of high-quality hydraulic fluid will provide around 150 hours of operation.

thank you for this very useful info

My electric log splitter makes the normal buzzing sound when turned on but the splitter does not move.

I have changed the hydraulic fluid, today but no change

It appears to have seized up

Do you have any suggestions

Thanks

Paul Granville

Hi Paul, Check that the plastic knob of the lever is screwed on fully. If this becomes unscrewed it prevents the lever from being pushed right down, stopping the log splitter from operating. You can view the video on this page: https://forest-master.com/ufaqs/the-motor-is-running-but-the-log-splitter-isnt-operating/

Bit late, but this might help someone else: it sounds very much as though you need to replace the motor capacitor. Make sure that it has the same voltage and capacitance (microFarad uF) rating. You can find them on eBay or Amazon. If that doesn’t help, it may be the centrifugal switch inside the motor housing.

Is it meant to state 3.5 – 7 litres of oil rather than gallons?

“ The majority of hydraulic fluid reservoirs will allow between 3.5 to 7 gallons largely ”

Nice catch, Wayne. Thanks!

I like what you said about the dipstick. My intake seems to be malfunctioning. I’ll have to have the hydraulics tested.

Bonjour?

J’ai une fendeuse FBV 10 T électrique, pour prendre le niveau d’huile il faut ; que le bras soit en position haut ou en bas? . j’ai essayez les deux et le nivaux n’est pas le même ! Merci pour l’éclaircissement.

Cordialement

Pour vérifier le niveau d’huile hydraulique dans la plupart des fendeuses de bûches, y compris divers modèles similaires à celui que vous avez mentionné (en supposant que le FBV 10 T soit une faute de frappe ou un modèle spécifique sur lequel je n’ai pas d’informations directes), la ligne directrice générale est de Vérifiez le niveau d’huile lorsque le vérin ou le bras est en position complètement rétractée ou abaissée. Cette pratique standard garantit que tout le fluide hydraulique est de retour dans le réservoir, fournissant une lecture précise du niveau d’huile sans la pression ou le déplacement qui peuvent se produire lorsque le vérin est étendu.

Voici une approche plus structurée basée sur des pratiques générales :

Assurez la sécurité : avant de vérifier l’huile, assurez-vous que la fendeuse de bûches est éteinte et déconnectée de toute source d’alimentation. Ceci afin d’assurer votre sécurité lors de l’inspection.

Position du vérin : placez le vérin ou le bras de la fendeuse de bûches en position complètement rétractée ou abaissée. Cela signifie que la partie mobile du séparateur doit être complètement en arrière ou en bas dans sa position de départ, et non étendue.

Vérifiez le niveau d’huile : localisez l’indicateur de niveau d’huile sur votre fendeuse de bûches, qui peut être un voyant, une jauge ou un bouchon de remplissage, selon votre modèle. Le niveau d’huile doit être vérifié à ce stade. Si vous utilisez une jauge, assurez-vous qu’elle est propre avant de la réinsérer pour le contrôle afin d’éviter toute lecture inexacte en raison de l’huile éventuellement tachée sur la jauge.

Lecture du niveau : Lorsque le vérin est complètement rétracté, le liquide hydraulique est entièrement dans le réservoir, et c’est à ce moment-là que vous devriez obtenir une lecture précise du niveau. S’il y a des écarts entre les lectures avec le vérin haut et bas, la position basse est généralement celle à laquelle vous devez faire confiance pour une évaluation précise du niveau d’huile.

Remplissage jusqu’au niveau correct : Si vous devez ajouter de l’huile hydraulique, assurez-vous d’utiliser le type spécifié par le fabricant de votre fendeuse de bûches. Remplissez lentement et vérifiez le niveau fréquemment pour éviter un remplissage excessif, car trop d’huile peut provoquer des problèmes de pression dans le système hydraulique.

Compte tenu de la variabilité des conceptions de fendeuses de bûches et des recommandations des fabricants, il est toujours préférable de consulter le manuel d’utilisation de votre modèle spécifique pour obtenir les conseils les plus précis sur les tâches de maintenance telles que la vérification de l’huile hydraulique. Si vous n’avez pas le manuel à portée de main ou s’il ne le précise pas, les directives ci-dessus doivent servir de bonne pratique générale. Cependant, en cas de doute ou si le manuel suggère le contraire, suivre les instructions spécifiques du fabricant est toujours la meilleure solution.