- Check the oil level sensor. The engine must have between 600ml and 650ml of oil. Any more or less will cut the ignition of the engine and prevent start-up.

- Check the hopper sensor. Ensure that the bolt underneath the hopper is securely screwed into the micro switch. If it’s not the case, the ignition will be cut and will not start.

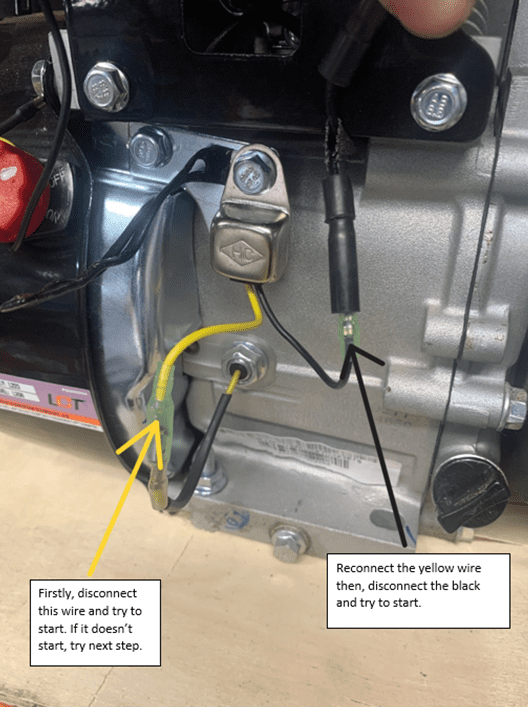

- If you have completed these two steps and the machine still does not start, temporarily deactivate the wires that connect these sensors. Follow the image below for directions.

Q: What are the two main reasons why the chipper will not start?

A: The two main reasons are the oil level sensor and the hopper sensor. Ensure that the engine has the correct oil level and that the bolt underneath the hopper is securely screwed into the micro switch.

Q: What can cause the ignition to be cut and prevent start-up?

A: The ignition can be cut due to an incorrect oil level, or an insecure bolt underneath the hopper which is not properly screwed into the microswitch.

Q: How can I find out if the hopper switch or the oil alert is at fault?

A: Temporarily deactivate the wires that connect these sensors. The wires circled in red tell us if the hopper switch is at fault and the wire circled in green tells us if the oil alert is at fault. Disconnect these wires and start the machine. Reconnect the wires, one by one, to find the issue.

Q: What should I do if the troubleshooting steps do not resolve the issue?

A: If the machine still does not start, please don’t hesitate to get back in touch with the manufacturer’s customer service to escalate the issue.