Forest Master – Frequently Asked Questions

Explore a range of frequently asked questions regarding our equipment, as well as general log splitting, gardening and forestry-related questions. Is your question not here? Submit a question by emailing us at info@forest-master.com.

6HP Petrol Mulcher (FM6DD-MUL)

Last Updated on July 30, 2021 by Forest Master

Wood is too dried out

The compact chipper series is designed primarily for chipping freshly cut wood. The FM6DD has been tested thoroughly chipping freshly cut hawthorn wood (slow-grown hardwood).

We recommend that the wood is chipped no longer than three days after cutting. After this date, the wood will begin to dry out, meaning the chipper blades then struggle to dig into the wood. This produces a sawdust-like waste from the exit chute, and the chipper will struggle to self-feed.

If the chipper is producing sawdust – this is a clear sign that the wood is dry. When chipping slow-grown hardwood like fruit trees (such as cherry or apple trees) you must ensure that you chip the material the same day that it is cut to ensure the machine operates at full effectiveness.

Last Updated on August 10, 2021 by Forest Master

This largely depends on the hardness of the wood you’re chipping. The harder the wood, the quicker the blades will need to be replaced.

However, the chipper is equipped with twin reversible blades. The reversible blades mean that you can simply switch the blades around when the first set start to dull, so you get a much longer life span on the blades.

We also stock spare blades on our website, should you need to have them replaced.

You can also sharpen your blades using an oil stone. Simply sharpen the edges of the blade, do not worry about taking out any dents or marks.

Last Updated on November 6, 2024 by Forest Master

All LCT petrol engines used on Forest Master products are compatible with E10 fuel. However as chippers and mulchers tend to be used infrequently, we strongly recommend that you add a fuel stabiliser to E10 or use a fuel that has been blended for use in garden equipment.

If unstabilised E10 fuel is left in the engine for a period without the engine being used then it evaporates and leaves a powdery residue in the fuel lines and carburettor. When you next use the engine, the powdery residue can get into the carburettor jet causing fuel starvation problems and requiring the carburettor to be fully cleaned.

If you do not use a fuel stabiliser or a specially blended fuel then before storing the machine for more than a few weeks, you need to drain it of all fuel and clean and dry the float bowl so there is no fuel left in it.

FM4DDE 4HP Electric Chipper

Last Updated on April 15, 2020 by Forest Master

The entrance leading direct to the cutter is 95 mm x 95 mm. The upper section has a CE plate fitted to restrict the size of cutting to 2 x 55mm holes with a slot joining the two holes which provides an entrance for side shoots and branches etc. The safety plate is not required for USA or Canada.

Last Updated on July 30, 2021 by Forest Master

Wood is too dried out

The compact chipper series is designed primarily for chipping freshly cut wood. The FM6DD has been tested thoroughly chipping freshly cut hawthorn wood (slow-grown hardwood).

We recommend that the wood is chipped no longer than three days after cutting. After this date, the wood will begin to dry out, meaning the chipper blades then struggle to dig into the wood. This produces a sawdust-like waste from the exit chute, and the chipper will struggle to self-feed.

If the chipper is producing sawdust – this is a clear sign that the wood is dry. When chipping slow-grown hardwood like fruit trees (such as cherry or apple trees) you must ensure that you chip the material the same day that it is cut to ensure the machine operates at full effectiveness.

Last Updated on August 10, 2021 by Forest Master

This largely depends on the hardness of the wood you’re chipping. The harder the wood, the quicker the blades will need to be replaced.

However, the chipper is equipped with twin reversible blades. The reversible blades mean that you can simply switch the blades around when the first set start to dull, so you get a much longer life span on the blades.

We also stock spare blades on our website, should you need to have them replaced.

You can also sharpen your blades using an oil stone. Simply sharpen the edges of the blade, do not worry about taking out any dents or marks.

Last Updated on July 6, 2020 by Forest Master

Both the FM6DD and the FM4DDE utilise a direct drive for performance, this means that there are no belts or chains that you need to adjust.

Last Updated on July 21, 2020 by Forest Master

In order to rotate the blades on any of our chippers, you much use a hex socket (6 sided) with no leading edge, this is important or you will round off the head.

Sometimes it helps to tighten a tiny bit before undoing the bolt.

When the process is complete, use a small amount of thread lock and screw back into position.

Last Updated on March 5, 2021 by Forest Master

Our compact chippers are built for the primary purpose of being a chipper and shredder. However, the chipper can still handle dry green waste such as laurel and conifer.

The cutting blades are set at a 0.5mm gap, these can be adjusted to be very close together which eliminates the gap for any leaves to bypass the cutting blades.

The FM6DD spins at a higher rate (3600 rpm v 2800 rpm) than the FM4DDE, the higher spin rate means that the chipper is able to produce smaller cuttings.

This machine is not capable of mulching wet green waste such as ivy or nettles, however, our mulching machine can easily mulch pretty much any material you throw at it. Take a further look at it by clicking here. FM6DD-MUL.

FM6DD 6HP Petrol Wood Chipper

Last Updated on March 29, 2021 by Forest Master

– Ensure that the oil level is higher than at least 600ml. The chipper should be filled with 600ml to 650ml of oil. Any less than 600ml of oil and the machine will not start. An oil alert will prevent the engine from starting.

– If the pull-start is tight, remove the black cover from the motor and rotate the big outer nut on the end of the shaft using finger and thumb. Check that the drum is rotating freely in both directions and ensure that they aren’t any blockages.

– If the drum is not moving freely using finger and thumb, remove the hopper and clear any blockages from the drum, spinning it back and forth using the nut on the motor to ensure the whole drum is clean of any possible blockage.

– Reposition the hopper back in to place and tightly secure the bolt (this is important as the bolt acts as a safety mechanism for the chipper). Ensure that the correct bolt is used when reassembling.

Last Updated on April 15, 2020 by Forest Master

The entrance leading direct to the cutter is 95 mm x 95 mm. The upper section has a CE plate fitted to restrict the size of cutting to 2 x 55mm holes with a slot joining the two holes which provides an entrance for side shoots and branches etc. The safety plate is not required for USA or Canada.

Last Updated on July 30, 2021 by Forest Master

Wood is too dried out

The compact chipper series is designed primarily for chipping freshly cut wood. The FM6DD has been tested thoroughly chipping freshly cut hawthorn wood (slow-grown hardwood).

We recommend that the wood is chipped no longer than three days after cutting. After this date, the wood will begin to dry out, meaning the chipper blades then struggle to dig into the wood. This produces a sawdust-like waste from the exit chute, and the chipper will struggle to self-feed.

If the chipper is producing sawdust – this is a clear sign that the wood is dry. When chipping slow-grown hardwood like fruit trees (such as cherry or apple trees) you must ensure that you chip the material the same day that it is cut to ensure the machine operates at full effectiveness.

Last Updated on August 10, 2021 by Forest Master

This largely depends on the hardness of the wood you’re chipping. The harder the wood, the quicker the blades will need to be replaced.

However, the chipper is equipped with twin reversible blades. The reversible blades mean that you can simply switch the blades around when the first set start to dull, so you get a much longer life span on the blades.

We also stock spare blades on our website, should you need to have them replaced.

You can also sharpen your blades using an oil stone. Simply sharpen the edges of the blade, do not worry about taking out any dents or marks.

Last Updated on July 6, 2020 by Forest Master

Both the FM6DD and the FM4DDE utilise a direct drive for performance, this means that there are no belts or chains that you need to adjust.

Last Updated on July 21, 2020 by Forest Master

In order to rotate the blades on any of our chippers, you much use a hex socket (6 sided) with no leading edge, this is important or you will round off the head.

Sometimes it helps to tighten a tiny bit before undoing the bolt.

When the process is complete, use a small amount of thread lock and screw back into position.

Last Updated on March 5, 2021 by Forest Master

Our compact chippers are built for the primary purpose of being a chipper and shredder. However, the chipper can still handle dry green waste such as laurel and conifer.

The cutting blades are set at a 0.5mm gap, these can be adjusted to be very close together which eliminates the gap for any leaves to bypass the cutting blades.

The FM6DD spins at a higher rate (3600 rpm v 2800 rpm) than the FM4DDE, the higher spin rate means that the chipper is able to produce smaller cuttings.

This machine is not capable of mulching wet green waste such as ivy or nettles, however, our mulching machine can easily mulch pretty much any material you throw at it. Take a further look at it by clicking here. FM6DD-MUL.

Last Updated on March 29, 2021 by Forest Master

The FM6DD requires at least 600ml of standard engine oil. When first starting the chipper, the oil should be flowing out of the lip of the filler. The chipper should be filled with 600ml to 650ml of oil. Any less than 600ml of oil and the machine will not start.

Last Updated on April 14, 2020 by Forest Master

We recommend that you maintain the oil of the chipper so that it is flowing out of the plastic dipstick hole, or 10mm above the top mark on the steel dipstick.

Last Updated on April 14, 2020 by Forest Master

If the pull cord is tight at all, do not keep pulling or you risk damaging the pull cord.

Remove the black cover cap from the motor and rotate the big outer nut on the end of the shaft using your finger and thumb. Check that the drum is rotating freely in both directions and ensure that they aren’t any blockages.

If the drum is not moving freely using your finger and thumb, then remove the hopper and clear any blockages from the drum, spinning it back and forth using the nut on the motor to ensure that the entire drum is clean of any possible blockage.

Position the hopper back into place and tightly secure the bolt. This is a crucial step as the bolt acts as a safety mechanism for the chipper . Also ensure that the correct bolt is used when reassembling.

Last Updated on July 6, 2020 by Forest Master

The FM6DD Petrol Wood Chipper is capable of chipping any fresh wood. We’ve thoroughly tested the chipper with hawthorn and beech wood, both when fresh and seasoned.

It’s capable of chipping the wood when fresh, but after three or so days the wood will begin to season, and this causes issues with chipping.

If you’re planning on chipping seasoned hard wood, then you will require a power fed chipper.

Last Updated on August 17, 2020 by Forest Master

A rare case of the engine sputtering and cutting out may be due to the way in which the petrol was filled into the tank. When filling up the chipper with petrol, ensure that the funnel is completely dry and that no water is entering into the tank.

If this happens, the water sinks directly to the bottom of the tank and the engine then attempts to burn this first, resulting in the engine spluttering and cutting out.

Last Updated on November 2, 2020 by Forest Master

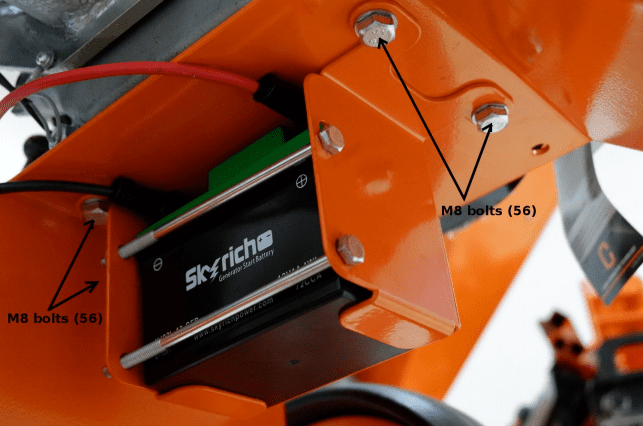

Assembly Parts:

Battery Tray – 1

M5x125 Bolt – 2

M5 Nut – 2

Battery – 1

Ignition Key – 2

If you’re reading the original FM6DD Manual; on step 5 of page 9 of the assembly instructions, attach the battery tray to the underside of the base (42) using the 4 bolts that secure the engine to the base.

Connect the battery wires to the terminals on the battery (red to positive (+)). Place the battery on the tray and secure using two M5 x 125 bolts and nuts.

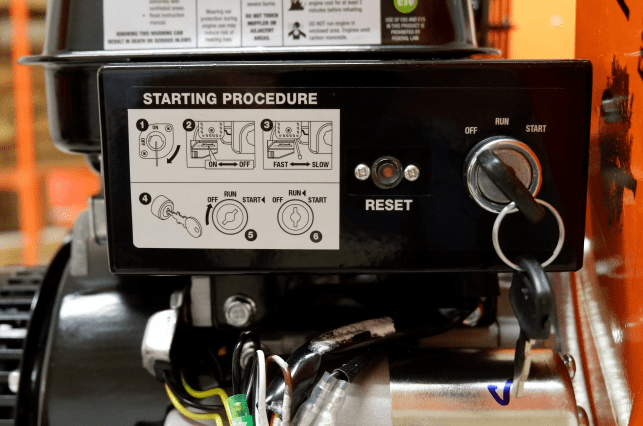

Starting the chipper

- Position your wood chipper on flat, dry ground and make sure the machine cannot be moved.

- Before starting, manually turn the drum to make sure it is not obstructed and moves smoothly.

- Make sure the fuel shut-off valve is in the “ON” position.

- Move the choke control level to the “CHOKE” position (should only be needed if the engine is warm or not starting)

- Move the throttle control lever towards the “FAST” position. Turn the ignition key to the “START” position. As soon as the engine starts, allow the key to turn back to the “RUN” position.

- Move the choke control lever (if used for cold engine) slowly back to the “RUN” position when the engine is running well.

- If the Wood Chipper has not been running (cold engine), warm up the engine by running the engine at half throttle for 3 to 4 minutes, then advance the engine throttle control to the maximum speed.

Stopping the chipper

- Move the throttle lever to “IDLE”.

- Turn the Ignition key to the “OFF” position.

Last Updated on November 6, 2024 by Forest Master

All LCT petrol engines used on Forest Master products are compatible with E10 fuel. However as chippers and mulchers tend to be used infrequently, we strongly recommend that you add a fuel stabiliser to E10 or use a fuel that has been blended for use in garden equipment.

If unstabilised E10 fuel is left in the engine for a period without the engine being used then it evaporates and leaves a powdery residue in the fuel lines and carburettor. When you next use the engine, the powdery residue can get into the carburettor jet causing fuel starvation problems and requiring the carburettor to be fully cleaned.

If you do not use a fuel stabiliser or a specially blended fuel then before storing the machine for more than a few weeks, you need to drain it of all fuel and clean and dry the float bowl so there is no fuel left in it.

Can’t find your question? Submit it below.