Last Updated on July 22, 2020 by Forest Master

The splitter should be turned upside down and left for a little while before removing the pump and motor assembly, this allows the oil to drain back into the tank. You can reuse all O-rings.

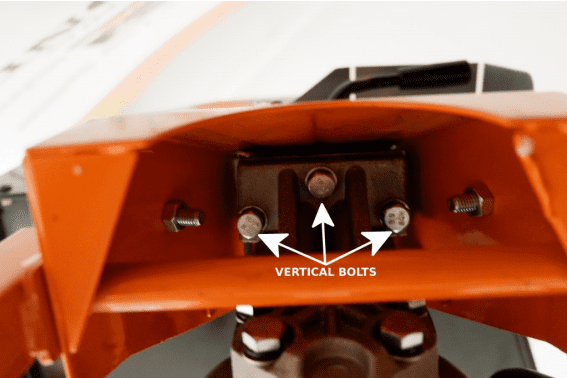

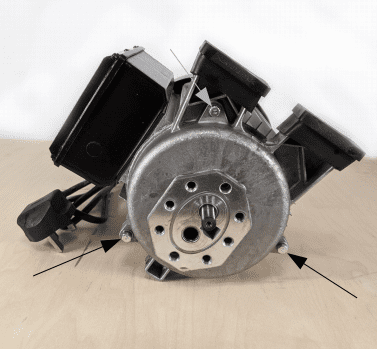

Undo the 3 bolts holding the pump bracket onto the underside of the splitter (you will require a socket and extension for this)

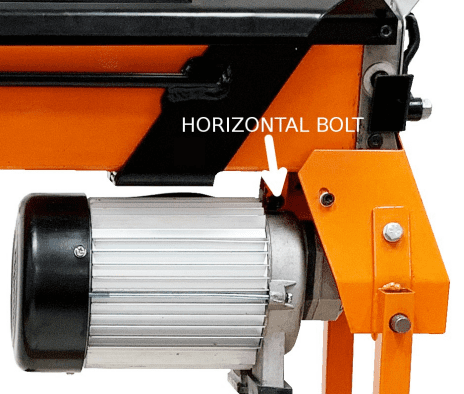

Also, remove the horizontal bolt collecting the back of the motor to the underside of the splitter body (demonstrated below)

Remove the complete motor and pump bracket assembly. There are two O-rings in holes in the face of the pump bracket, ensure you do not lose these.

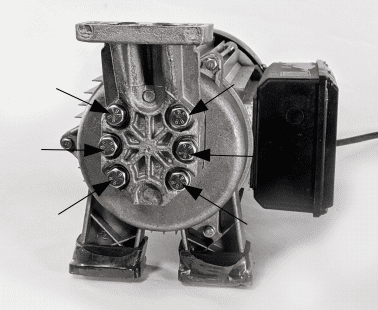

Undo the 6 bolts holding the pump bracket to the electric motor and remove the motor along with the pump plate and gears.

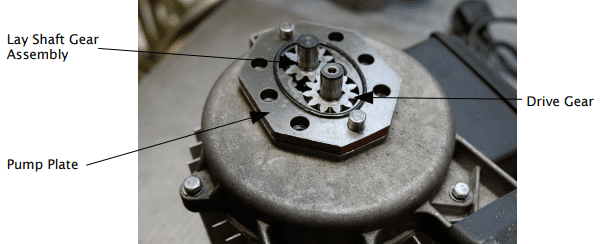

You can then remove the pump plate, lay shaft gear assembly and the drive gear from the motor shaft. Demonstrated below.

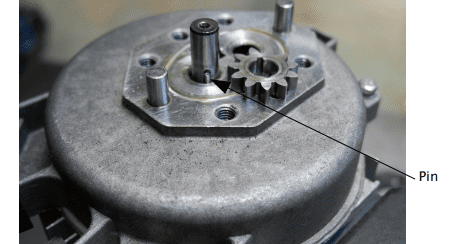

The next step is to remove the small pin (part 70) which keys the drive gear to the motor shaft. Do not misplace this as the pump will not drive without it.

You can now undo the three long bolts holding the end cover to the motor and then remove the end cover. Note that if you have no removed the small pin (70) then you cannot draw the shaft through the cover.

Fit the cover to the new short motor.

Insert the pin (70) into the slot in the motor shaft and fit the drive gear.

Refit the upper gear shaft, geat and the pump plate. Ensure that the two ovalO-rings are still seated in their grooves.

Attach the motor assembly to the pump bracket with the 6 bolts. Be careful not to overtighten the bolts as this will cause the pump to jam. The normal torque is 12 – 14 flbs.

Refits the pump and motor assembly to the log splitter. Ensure the two O-rings in the top of the pump are seated correctly before fitting the assembly.

If after fitting, the motor turns but the pump does not function, the likely cause is that you have not fitted the pin into the motor drive shaft and therefore the gear is not being driven.

If the motor does not turn after fitting, the 6 bolts are most likely too tight. Undo each bolt a quarter of a turn and try the motor again.